Description

We show this item as a reminder of the past and bring attention to the record and stylus being where mechanical energy converts to the electronic signal for amplification.

Note… not all records get cleaned the same way.

Today,with vinyl records there are many brushes and other options available that do a far more complete job with cleaning the stylus before you play your record. For many value packed options at low prices Amazon.com does enough volume with these kinds of supplies it is the place to shop.

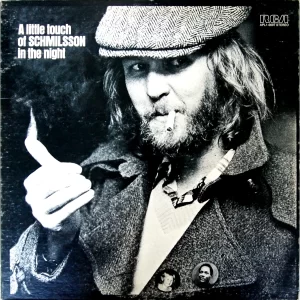

Yesterday, with shellac, 78 rpm and 80 rpm records soap, water and a soft fine hair brush are likely your best friend. Care taken with overly hot water has risks to worn shellac records that warped easily.

Before that, Edison’s Diamond Disc and cylinders were/are at danger from the impact humidity/water have on their stability. A Diamond disc was a mix of phenol, formaldehyde, wood-flour ( or in later years clay to offset moisture separation ) and solvent that was coated phenolic resin varnish (i.e. they called it “condensite) that ended up weighing just over half a pound and a quarter of an inch thick. Unlike other discs the groves modulated up and down instead of side to side. These discs were more expensive to manufacture and enjoyed the reputation that they could play 1000 times without wearing when played with the Edison diamond needle. The lamination composition however made layer separation more likely in humid environments. The bigger problem for these records came from being played on non Edison phonographs using a steel stylus. With the Edison stylus wear was not an issue but steel stylus use quickly destroyed the record quality. No amount of cleaning will recover that kind of damage.

Cylinder records generally available now are the blue and purple Amerol ones made of celluloid with a plaster of paris core. Cleaning them includes keeping moisture and heat away from that core. Moisture and/or heat will cause that core to expand which in turn warps the celluloid at best or crack at worst.